In 2020, Envitec LLC developed and approved a project of an agro-industrial complex for Goodvalley Ukraine, which includes a first-stage biogas plant with a capacity of 1.5 mW and a second stage with 3 mW, as well as a feed mill workshop with a capacity of 22 tons / h. For us, reliability, transparency and relationships with partners are just as important as economic aspects.

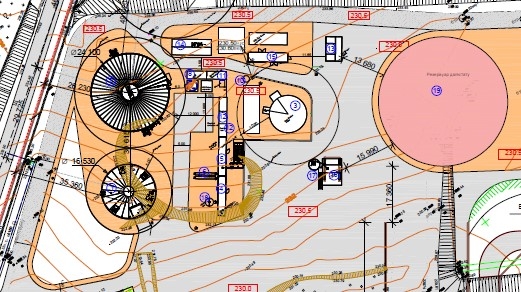

Figure 1. Fragment of the general plan of the project of construction of the shop of processing of organic agricultural wastes of production and shop on production of compound feeds for Goodvalley Ukraine.

The agricultural waste processing plant is actually a plant for the production of biogas from agricultural waste of a pig farm in the village of Tustan - manure, slaughterhouse waste, silage, chaff.

The project envisages the production of biogas in the amount of 4.8 million m3/year by anaerobic fermentation on a biogas plant with a volume of 10.0 thousand m3. Electricity and heat will be generated by burning biogas in a 1.5 MW cogeneration unit.

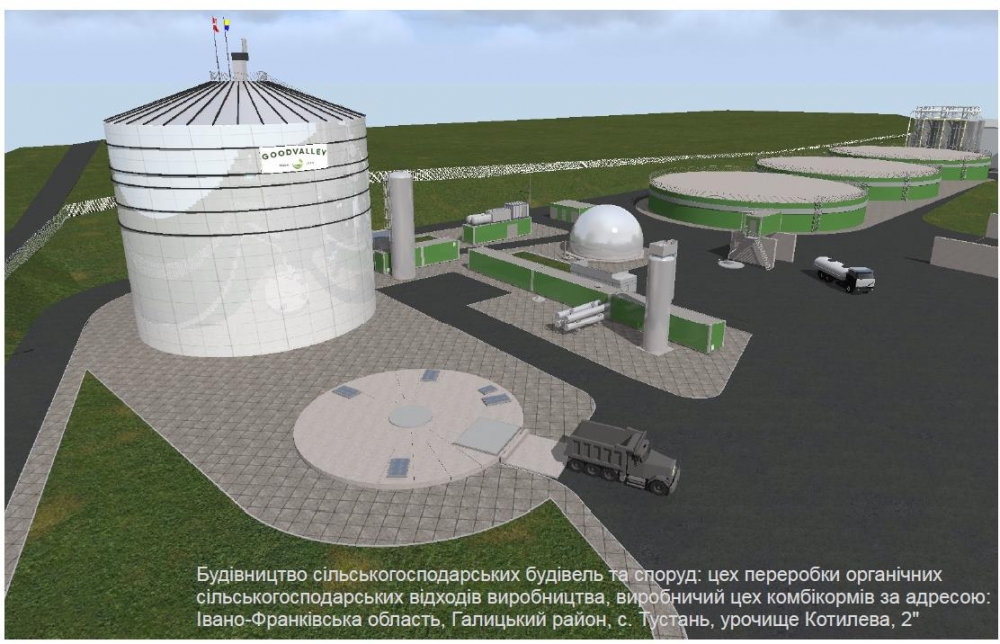

Figure 2.Biogas plant.

The biogas plant operates on the principle of anaerobic fermentation in the complete absence of oxygen and maintaining a constant temperature. The biogas produced in the bioreactor, which has passed all technological stages of preparation, will be supplied by a gas blower for further combustion in a cogeneration unit (CHP) or boiler house.

The project provides for the separation of digestate into solid and liquid fractions. The solid fraction can be applied directly to the fields, and the liquid fraction can be stored in special tanks until the moment of demand.

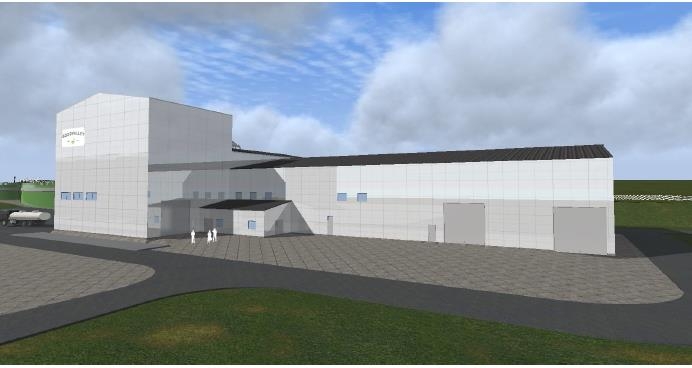

The feed shop is designed for feed preparation by mechanical, thermal, chemical and biochemical action aimed at improving the nutritional and taste qualities of feed.

The construction capacity of the feed mill is 22 t / hour.

Raw materials for the production of feed mixtures are beet pulp of 1,500 tons, soybean meal, sunflower meal, sunflower meal.

The end result of the feed shop is the issuance of the finished product in the form of feed mixtures, such as Starter, Multi, Speed, Rosta, Grower, Lakta, Gesta.

Figure 3. Feed mill shop.

The main achievements of the project are:

- The Customer got profits from his waste, i.e. production of "green energy" and biogas that can be sold

- Obtaining thermal energy to meet their own needs

- Zero emissions into the atmosphere

- Avoiding the danger of waste infiltration into underground horizons

- Avoid storage of production waste on the territory of the pig farm, as well as relevant odors

- Creation of new job places

- Improving the general ecological condition of the surrounding areas